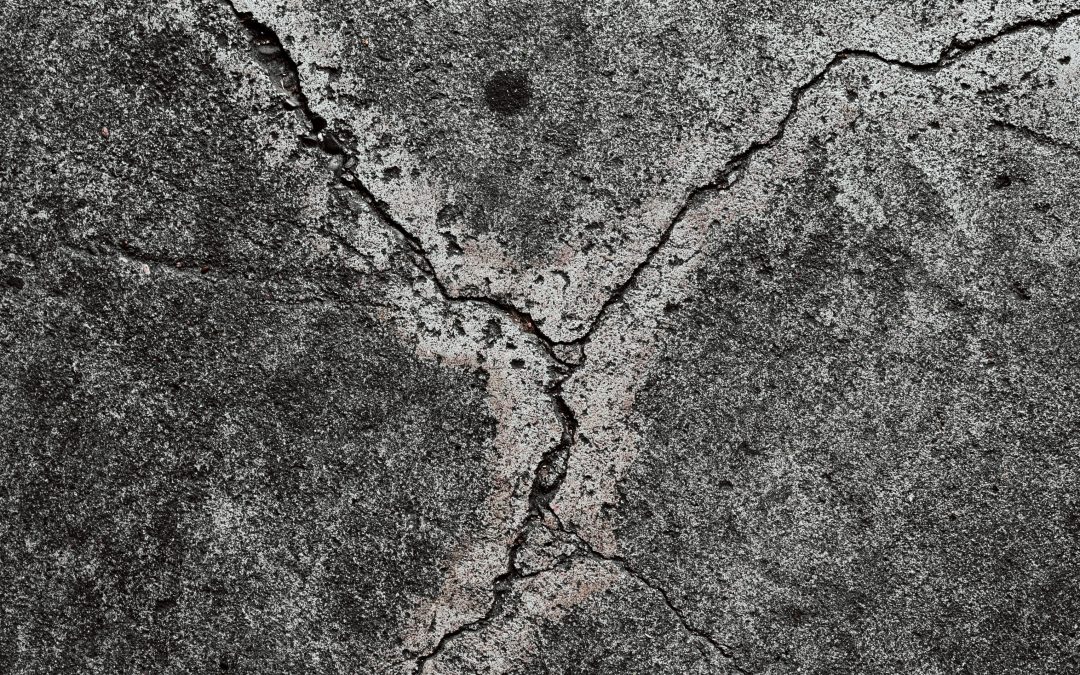

A concrete garage floor that is showing signs of cracking could have serious underlying structural difficulties. There will be no way for us as sellers or owners to determine if they are sincere.

The good news is that garage floor cracks are extremely common and usually don’t mean anything serious has gone wrong with the structure. There are, however, a handful that point to the necessity for repair or the possibility of a structural issue.

Helping a client in their own home to clear out clutter and organise their belongings is a very individual service. It’s essential that you have Garage Smart Garage Storage Solutions the right team for this task.

Why Do Garage Floors Crack?

Speak to us if you’re looking for premium garage storage solutions in Australia.

A garage floor will crack over time. Concrete cannot be stretched or bent without cracking because it is not ductile. However, it does shrink and expand depending on temperature, which causes it to crack.

Most slabs have expansion joints installed specifically for this purpose. Deep grooves or saw cut connections in the concrete create the illusion of four individual slabs within a standard two-car garage. Since cracks are weakest along the groove, they tend to stay in one place rather than spreading out throughout the surface.

Although contraction joints do their job, other areas of the concrete may still break owing to curing problems, shifting soil, or other factors outside of your control. The majority of cracks, while unsightly, do not compromise the integrity of the building. As a result, they may be easily modified to accommodate various types of garage flooring after being damaged.

Common Reasons There are Cracks in Your Garage Floor

The great news is that problems with a concrete floor are uncommon. It’s not hard to repair most of them. When we say they’re easy, we mean they don’t call for a lot of training or expensive equipment. Unfortunately, considerable effort is needed to complete them. As is the case with so many endeavours of this type, the most important step is the preparation. Larger surface repairs benefit greatly from the use of power tools.

Inevitably, concrete will break when being worked on. Garage floor cracks are considered serious if the aperture is 1/8 inch or wider and/or if the crack has raised edges on one side.

Reasons why garage floors often develop cracks are discussed here.

Expansion

Concrete can take a beating without breaking, but its tensile strength is quite weak. So, it’s not really malleable or stretchy. Cracking may occur due to extreme changes in temperature.

Shrinkage

Experiencing shrinkage-related cracks is normal and usually harmless. Since concrete naturally shrinks during the curing process, it is not unusual for even freshly poured slabs to already have a few small cracks in them.

Settlement

Settlement is what happens when the ground beneath your home or building shifts and sinks. Garage flooring are susceptible to cracking due to the strain caused by typical, gradual settlement that occurs over time. In most cases, settlement fractures will do greater damage than shrinkage cracks. In the end, the crack’s width and whether or not it widens determine its severity.

Cracks in the foundation that have already begun to settle are like open buckets, just waiting to fill with water. This pooling of water, however, can cause more serious issues, such as the settling of your garage’s floors. The possibility of flooding is substantially increased in this way.

The weight of tyres exerts a disproportionate amount of force on some parts of your garage, depending on its configuration. This can lead to natural cracking and settlement, especially in the garage’s corners.

If there are large cracks in the foundation and one side is noticeably higher than the other, this could be a sign of more serious settlement problems. The sooner problems are identified, the less damage can be done.

Bad Installation

If your garage floor has many cracks, the original construction may be to blame. It’s possible that the builders laid down too little gravel for the foundation, didn’t use enough rebar, or both. Here are some common blunders:

- There isn’t enough gravel.

- Concrete has a too low mpa.

- improper base, disturbed soil, or uneven terrain

An attached garage can become a source of water damage to a house if the slab was poured at an improper level. Moreover, the slab for the garage floor should be poured so that it slopes slightly away from the house to aid drainage.

Flooding / Source of Underground Water

Water is a major contributor to the onset of cracks in a garage floor, especially if it is not able to escape the area as it should. Soils that are dense from clay or other materials tend to hold onto the water they receive. Extreme strain could be exerted on the garage floor if the water-rich soil beneath it freezes and expands over the winter. Heaving and cracking can result from this.

As the area most exposed to the cold and ice, the garage door is a popular place for cracks to appear. Seal any potential water entry points along the outside of your garage. The exterior soil level should be approximately six inches lower than the bottom of your garage.

What To Look For When Diagnosing A Hazardous Garage Floor Issue

We certainly have no right to dictate your actions, but here are my thoughts, nonetheless. In-car flooring Extensive destruction and severe structural problems necessitate expert repair. The following symptoms suggest a deeper issue:

- cracks with a higher side on one side than the other

- crumbling or cracking in the low areas

- a garage floor that is always damp

- a pool of water that won’t dry up in the garage

- Is the gap staying the same size or expanding? If you observe the fracture widening, it may be a sign of a more serious structural issue if you do nothing to fix it.

- Is the crack deep enough to cause a tripping hazard if it’s on a horizontal surface like a floor or slab?

- How big of a crack is there in the wall or floor of the house to let water in? (Check out Crack Repair in the Foundation and the Basement.)

- Is there a problem with sanitization or crack-trapped dirt?

- Is the hole aesthetically offensive and in a prominent spot?

These are all signs that something more serious is going on under your garage floor. The subfloor may be under siege from a big quantity of water. Garage floors that leak water will eventually develop structural issues. Consult an expert in the field of concrete for an accurate assessment of the damage and advice on how to fix it. Any temporary solution to a deeper issue will eventually fail. With enough pressure, water can break apart even the toughest concrete. DIY mortar or epoxy won’t be able to stop that.

Repairing Cracks In The Floor Of Your Garage

When repairing a crack, the first step is to follow the crack’s path. The loose edges and debris within the fracture are removed with a hammer and cold chisel. The strength of the repair depends on the surface on which it is adhered.

You can pick up a cold chisel at any hardware store or on Amazon if you don’t already have one. Those equipped with a handguard are our top pick.

In order to follow the crack, you should angle your cold chisel so that it parallels the fracture. Use a heavy hammer or a portable sledgehammer to pound on it. Hitting the chisel with a hammer will dislodge any debris. Just keep going in this direction until you’ve followed the crack all the way through.

Using a shop vac, remove any loose debris, and then scrub the crack thoroughly with a sharp wire brush. This will get rid of any weak laitance and get the surface ready for the repair compound. After vacuuming up the void once more, you can proceed with the repair.

Always read and follow a product’s instructions before using it. To eliminate the possibility of air bubbles, it is important to massage a 2-part epoxy sand slurry or 2-part epoxy gel into the crack thoroughly. After it has been mixed in, a smooth finish should be achieved by trowelling before the substance sets. Keep an eye out for any voids that might require filling in with repair material.

Silica sand should be used to fill in around three-quarters of a fracture before a product like Simpson Strong-Tie is applied. Simpson Strong-Tie should be used above the sand and below the concrete. Wait a few minutes for it to soak in, and then apply again to the bare regions.

After that, sprinkle some additional sand lightly over the patch and wait 20 minutes. Once it has dried, you can remove the surface coating with a putty knife or paint scraper.

After cracks in a garage floor have been repaired, the area is ground down to a smooth transition before painting or adding an epoxy finish. In this way, the coating will be able to hide the majority of repairs.

It is not necessary to chisel fractures in order to create an inverted or backward-angled cut, contrary to popular belief. This is necessary only when replacing big sections of concrete or cement patch.

Speak to us if you’re looking for elite garage storage solutions in Melbourne.

The concrete will not rise out thanks to the perpendicular incision because fresh concrete does not stick well to dry concrete. However, polyurethane, epoxy, and polyurea crack repair solutions establish a tenacious bind to properly prepared concrete and do not require an inverted cut to remain in place.

A small 4” angle grinder fitted with a crack chasing masonry wheel is another method that achieves good results when chasing cracks. A smooth, even groove is cut into the concrete by the wheel’s tapered design.

Partially filling the fissure with silica sand is the ideal approach when healing deep cracks. The repair material won’t be able to sink too far into the concrete, saving time and effort. It prevents you from having to use too much material or leaving holes that will need to be filled later.

We provide a comprehensive, expert decluttering and organising service. Are you becoming increasingly annoyed by your inability to keep your home clean and organised? Let GarageSmart Garage Storage Solutions handle it.

Products Recommended For Crack Repair

When repairing or filling cracks, it’s best to use a sandable compound made from epoxy, polyurethane, or polyurea. This has a higher strength after curing than concrete and will also seal off any potential leaks caused by moisture. They can be prepared for painting or epoxy coating by grinding or sanding until they are flat with the concrete.

If you need to patch cracks in concrete, don’t waste your money on low-quality options made with water or latex. Because of how accessible and affordable they are, they are the ones most hardware stores stock. The trouble with them is that they can’t be sanded, they don’t take paint, and they shrink and separate from the fix as time passes. Self-levelling sealants should also be avoided because their primary function is in sealing concrete control joints.

A caulking gun is needed to use the product’s included 9-ounce cartridge. Within the sealed container, the 2-component epoxy is kept in two distinct halves. The cartridge’s self-mixing tip makes it unnecessary to combine the two components before use, streamlining the application process.

In order to fix fractures in a garage floor that are less than 1/8″ broad, this material is ideal because of how smoothly it runs. It is recommended to use clean play sand or silica sand to partially fill the crack before applying this product if the crack is deep or wider than 1/8 inches. The epoxy will not be able to rush into the fissure any farther than is absolutely necessary.

We’ve also had great results with PC-Concrete Epoxy Crack Repair, which can be purchased on Amazon. Since this epoxy is more viscous, you’ll need to use a putty knife to spread it into the crevice. It is also useful for patching up minor imperfections in the pavement. It has a self-mixing tip, just like other cartridge epoxy repair supplies.

We enjoy PC-Concrete since it hardens completely within just 4 hours. What this implies is that you can fix your cracks and then grind them flush in the same day.

Rust-Epoxy Shield Oleum’s Concrete Patch is the third product we endorse. This, too, is a 2-component epoxy that must be combined on a flat surface like cardboard or wood.

Make sure you don’t mash up too much of each component into the other at once when you’re combining them. You won’t have much time to work with the epoxy before it sets. However, you only have so much time before the epoxy sets up too thickly to be of any use, so make sure all of your repairs are complete before you start.

It’s sold on Amazon, and it’s also available at select hardware stores.

Epoxy concrete patch kits in 1-gallon or bigger containers are your best bet if you need to fix a lot of cracks greater than 1/4 inch across. For longer, wider, and deeper gaps in the garage floor, this product is a great option.

Epoxy gels with sand aggregates can be used as fillers, and they typically contain 100% solids. A concrete float can be used to smooth it out after it has been applied to the fissure. The Xtreme Set 100 from Legacy Industrial is one of the best products we’ve evaluated recently.

Even if you go to a home improvement store, you won’t be able to find anything like this. They can be seen more frequently in the expert floor coating business and are typically only available for purchase online. You can buy one of these kits from any retailer.

Speak to us if you’re looking for garage storage solutions in Sydney.

Will The Coatings Allow The Cracks To Reappear?

We have to say that “maybe” is the most accurate answer. There are no assurances that cracking will not occur again because several factors, such as slab expansion, slab vibration, and contraction, and hydrostatic vapour pressure, can cause the original crack to reappear or for new cracks to form that show through the coating. Anyone who claims they can guarantee a concrete slab won’t crack or that cracks won’t show through a coating is making an uninformed claim.

In addition, the use of a coating, such as a decorative chip, lessens the possibility that a tiny, tight crack will be readily apparent in the coatings.

Garage flooring frequently develops cracks, and sometimes they emerge immediately after the floor is poured. Over the course of the first year or two, you may notice some others as a result of the house settling.

Cracks are more common in older homes and homes constructed on expansive soils, but even if you find cracks, you still need to determine if they are major or just typical for the home’s age and location.

Cracks in concrete slabs can occur for a variety of causes, and in most cases, they won’t indicate any major difficulties with the foundation or the structure. Any owner or potential buyer in such a situation would be wise to conduct a thorough inspection of the home.

Conclusion

Cracked garage concrete may indicate structural problems. Surface cracks rarely indicate structural problems. However, certain signs suggest maintenance or structural problems. For example, settlement tension breaks garage floors. Settlement is the ground sinking and shifting beneath a structure.

Open foundation fractures might flood. Freezing and thawing garage door cracks may signal a structural issue. Concrete specialists can provide an honest assessment and repair suggestions. Substrate effects repair durability. After vacuuming, scrape the crack.

Filling the fissure halfway with silica sand works well. Polyurea, epoxy, and polyurethane crack repair treatments adhere well to prepared concrete. Save money on good concrete crack repair options. The PC-Concrete self-mixing tip avoids pre-mixing. Use a putty knife to apply this heavier epoxy.

Legacy Industrial’s Xtreme Set 100 is a great product we tested. Home improvement stores and Amazon sell it. This solution suits larger, deeper, and longer garage floor cracks. Garage floorboards might crack quickly after pouring. Decorative chips can hide a tiny, narrow fissure. Before buying, homeowners and purchasers should inspect the property.

Content Summary

- A concrete garage floor showing signs of cracking could have serious underlying structural difficulties.

- However, a handful point to the necessity for repair or the possibility of a structural issue.

- Speak to us if you’re looking for premium garage storage solutions in Australia.

- A garage floor will crack over time.

- The great news is that problems with a concrete floor are uncommon.

- It’s not hard to repair most of them.

- Garage floor cracks are considered serious if the aperture is 1/8 inch or wider and the crack has raised edges on one side.

- In most cases, settlement fractures will do greater damage than shrinkage cracks.

- However, this water pooling can cause more serious issues, such as settling your garage’s floors.

- This can lead to natural cracking and settlement, especially in the garage’s corners.

- If there are large cracks in the foundation and one side is noticeably higher than the other, this could be a sign of more serious settlement problems.

- Bad Installation If your garage floor has many cracks, the original construction may be to blame.

- Flooding / Source of Underground Water Water is a major contributor to the onset of cracks in a garage floor, especially if it cannot escape the area as it should.

- As the area is most exposed to the cold and ice, the garage door is a popular place for cracks to appear.

- Seal any potential water entry points along the outside of your garage.

- These are all signs that something more serious is under your garage floor.

- Please consult an expert in the field of concrete for an accurate assessment of the damage and advice on how to fix it.

- The loose edges and debris within the fracture are removed with a hammer and cold chisel.

- Hitting the chisel with a hammer will dislodge any debris.

- Using a shop vac, remove any loose debris and scrub the crack thoroughly with a sharp wire brush.

- To eliminate the possibility of air bubbles, it is important to massage a 2-part epoxy sand slurry or 2-part epoxy gel into the crack thoroughly.

- Simpson Strong-Tie should be used above the sand and below the concrete.

- Once it has dried, you can remove the surface coating with a putty knife or paint scraper.

- A small 4″ angle grinder fitted with a crack-chasing masonry wheel is another method that achieves good results when chasing cracks.

- The repair material won’t be able to sink too far into the concrete, saving time and effort.

- If you need to patch concrete cracks, save money on low-quality options made with water or latex.

- A caulking gun is needed to use the product’s included 9-ounce cartridge.

- It is recommended to use clean play sand or silica sand to partially fill the crack before applying this product if the crack is deep or wider than 1/8 inch.

- It has a self-mixing tip, just like other cartridge epoxy repair supplies.

- Make sure you only mash up a little of each component into the other at once when you’re combining them.

- However, you only have so much time before the epoxy sets up too thickly to be of any use, so make sure all of your repairs are complete before you start.

- Epoxy concrete patch kits in 1-gallon or bigger containers are your best bet if you need to fix many cracks greater than 1/4 inch across.

- This product is a great option for longer, wider, and deeper gaps in the garage floor.

- A concrete float can smooth it out after applying it to the fissure.

- Speak to us if you’re looking for garage storage solutions in Sydney.

- Anyone who claims they can guarantee a concrete slab won’t crack or that cracks won’t show through a coating is making an uninformed claim.

- Over the first year or two, you may notice some others due to the house settling.

- Cracks are more common in older homes and homes constructed on expansive soils, but even if you find cracks, you still need to determine if they are major or just typical for the home’s age and location.

- Cracks in concrete slabs can occur for various causes, and in most cases, they won’t indicate any major difficulties with the foundation or the structure.

- Any owner or potential buyer in such a situation would be wise to conduct a thorough inspection of the home.

FAQs About Floor Cracks

How long should I wait before fixing a cracked floor?

Floor cracks are usually nothing to be concerned about. If the cracks begin to shift vertically, though, you may have cause for concern because this may indicate that the building is settling.

If there are gaps between the floor and the wall, how do you fix them?

Caulking. Create a watertight seal with silicone caulk. Use silicone caulk to seal the grout between the tiles in your bathroom or shower to prevent water from getting in. Silicone caulk can be found in hardware stores, home improvement centres, and on the web.

How quickly do floor tiles crack?

While both ceramic and porcelain tiles are quite durable, they can break if they experience a particularly forceful impact, such as being dropped from a great height. This is especially true if the tiles were improperly installed to begin with.

Are there no crack-free concrete floors?

It’s natural to assume that poor workmanship is to blame when you spot a fracture in a concrete floor or wall. Actually, cracks in concrete are rather common, and in some cases even unavoidable. Following is an explanation of the six most frequent varieties of concrete fractures.

Should Concrete Holes Be Patched?

Because of the unyielding structure of concrete, cracks are always present in a concrete slab. Cracks in your slab can be caused by uneven drying, shrinkage, and temperature variations. It is essential to seal any cracks that appear in order to prevent water seepage and further damage.