Sheds are a terrific way to add some more room for the items you ‘need,’ whether it’s a tiny shed for a few gardening equipment or a large shed large enough to store your cars, jet skis, ATVs, and boat. Rust and corrosion are only two of the maintenance concerns you’ll have to keep in mind for any size shed.

Rust and corrosion, which are often overlooked by shed owners, can cause significant damage to your storage shed and force you to replace it entirely if you don’t take the required precautions to keep them at bay. There are a few things you can do to prevent rust and corrosion in your shed over the winter, regardless of whether you live near saltwater or in a hot, humid climate.

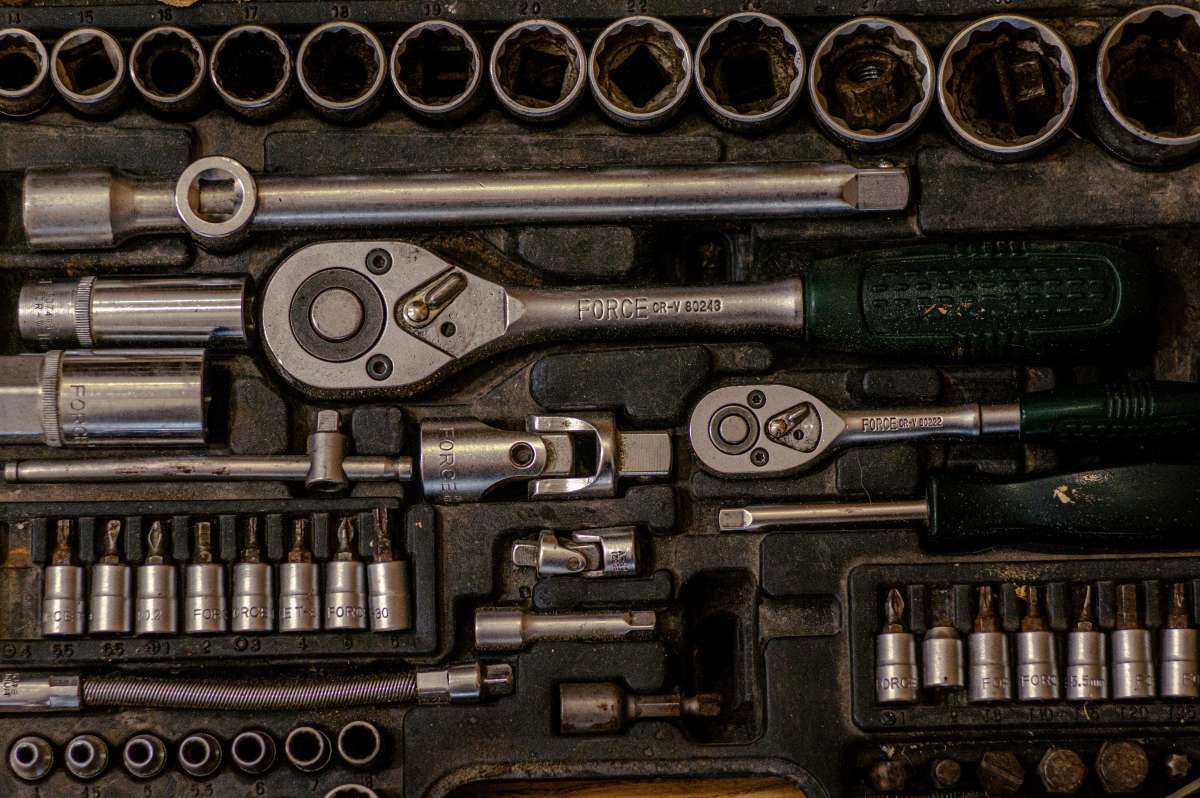

Your garage is the perfect place to store your tools, whether you have a few hand tools for light household projects or dozens of power equipment for major building projects. However, even if you store them in a garage, they may still rust.

Most importantly, keep in mind that rust may be avoided with the right equipment, storage solutions, and maintenance practises.

Even in a garage, your metal tools can rust. Metal corrodes and oxidises when exposed to moisture and oxygen. Although rusting of metal tools is unavoidable, it can be delayed by controlling humidity, increasing ventilation, and coating tools with a protective substance.

Few people in colder climates give much care to the tools they’ve stashed away in the garage, barn, shop, or shed when winter arrives. Due to the fact that many tools can be negatively affected by prolonged exposure to cold, this is a potentially costly mistake. That’s especially important to remember when working with power tools in frigid conditions.

Which Tools Are Prone to Rust in a Garage?

Metal tool rust is an issue that frequently arises. Sadly, that is a fact that cannot be altered.

Not only is rusted metal dangerous, but it also corrodes your equipment. Your tools’ strength will gradually but steadily decrease due to corrosion, which is a silent destroyer.

Even brand-new tools might become drab and useless in a few of months.

You must first recognise the symptoms of corrosion on different metals in order to learn how to prevent your tools from rusting.

- Iron: When it sustains damage, any tool made, at least in part, of iron will rust within 3 to 5 days. Two of the main causes of rust are oxygen and moisture, which can be attracted by small nicks or porous surfaces.

- Steel: Since iron makes up a significant portion of steel, it makes sense that rust can also affect steel. Thankfully, the majority of stainless steel tools have been coated to resist rust. You should still take safety measures to help prevent it.

- Metals like copper don’t rust. But it does oxidise, and oxidation is a type of corrosion. Because copper wiring is so hard to destroy, it is frequently used in electrical projects. Unfortunately, copper isn’t as strong as steel, thus it’s unlikely that your hand tools are constructed of copper. Even yet, there are certain unique instruments made of copper, therefore it’s vital to care for them as well.

- Aluminum: Aluminum can form an oxidised corrosive layer even if it won’t rust. As long as you store the tools properly and don’t treat them improperly, the majority of aluminium tools are made to resist oxidation for quite a while.

Although only iron and steel tools are known to rust when exposed to dampness, all tools will eventually undergo corrosion.

You still need to take care of your tools so they don’t rust, even if you store them in a garage.

How to Prevent Rusting in Your Tools

The best way to get rid of rust is to prevent it in the first place. It doesn’t matter whether you keep your tools in the garage or the closet to prevent rusting.

By adhering to these simple suggestions, you can prevent rust. Using them ought to increase the longevity of your tools.

- Use an anticorrosive spray cleaner, such as the common WD-40, to remove rust. The red-cap version of WD-40 will work just fine, but if you really want to prevent rust, you should purchase the WD40 Specialist

- Corrosion Inhibitor Spray. Your instruments will be protected while they dry with a short spray. It will help prevent corrosion for a few months.

halting the bleeding Even while we prefer to act as though our tools are indestructible, they aren’t nearly as robust as you may think. The minor dents and chips you made by smashing them into your toolbox can develop rust. By keeping your toolbox organised, you can avoid a lot of accidents. - Dehumidification of a garage Rust prevention for your tools can be achieved by dehumidifying your garage. If you live in a region with a lot of humidity, like I do, a dehumidifier is a must-have. If you’re interested, you can see the one I keep in my garage here.

- Ventilate your garage with fresh air. Another method for lowering humidity is to move the air around.

- You can stop moisture from building up on your equipment if you can instal a few fans around the area.

- With the aid of a dehumidifier and a garage fan, rust can be delayed for a long time.

- Put your toolkit in a safe place. When people hear this, they typically picture a toolbox, but anything that keeps people inside is beneficial. If you neglect your garage tools, disaster is just a matter of time.

How to Remove Rust from Tools

If you see that some of your garage tools are beginning to rust, the best course of action is to detect it as soon as possible. If the rust is removed before it has a chance to weaken the metal, tools may still be used.

Here is a quick and easy 4-step method to restore your garage tools if they have corroded over time:

- Make a tight ball out of some aluminium foil. It must be secure enough to prevent deformation when rubbed against musical instruments.

- To clean the dishes, fill a bowl with warm water and a few drops of dish soap. If the temperature is too low, the metal will corrode more severely.

- To get rid of tenacious rust, all you need is soapy water and an aluminium foil ball. Instead of moving linearly, turn your movements into circles. The rust will liquefy and simply peel off.

- Repeat step three as necessary to achieve the desired results before drying your instruments and storing them in the garage. If even a small amount of moisture is left on the tools, rust may reappear.

Another method is to soak it in WD40 Specialist Rust Remover Soak. You can soak your tools and let the solution handle the difficult task of rust removal. The tools are cleaned with the liquid, the rust is eliminated, and they are then returned to their previous state.

Here are some tips for storing tools safely in the wintertime

Hand Tool Cabinet

The majority of hand tools can last for extended periods of time in the freezing conditions of a garage or storage shed without experiencing damage. Many metal and plastic components become brittle and easily breakable in subzero temperatures. To prevent this from happening, make it a routine to bring your hand tools inside from the garage or shed at least an hour before you want to use them.

Additionally, remember that metal tools corrode with time. Extremes in temperature and humidity can hasten that process. Try to find a safe location inside the house to store your tools if you are concerned about rust. Before storing them indoors, give them a thorough cleaning and consider treating any metal parts with fine oil or a rust-preventative.

In extremely cold climates where the air is regularly dry, tools are less likely to rust throughout the winter. Rust might become an issue if you bring them inside the house, particularly if you intend to store them in the basement. Furthermore, rust is more likely to happen if you live near the beach where the winters are less bitterly cold and more humid. Use a dehumidifier there if the air in the area where you keep your tools has a tendency to grow moist.

Garden Tool Cabinet

Check for rust spots after washing and drying them, then scrub them with a wire brush or steel wool. Rub the metal with some WD-40 or another light oil that has been applied on a cloth. Check for splinters, sand handles smooth, and coat any wooden components that might have cracked or splintered in the dry winter air with linseed oil. Shovels and other digging implements should be kept high off the ground, on a wall. Garden sprayers need to be well cleaned.

Clean the underside of your lawnmower deck to get rid of any stray grass clippings, and scrub the power tiller blades well to get rid of any corrosion or rust.

Power Tool Cabinet

If used in extremely cold temperatures, your power tools, like any powered instrument, may encounter considerable strain. The tension of metal parts moving from extremely cold to extremely heated temperatures at the engine’s core may cause some tools to malfunction before they should. Power tools should be stored indoors if they are to be used all winter due to the cold.

It is advised to wait a few minutes for the motor of an electric tool to warm up so that the oil and grease within can reach working temperature. A saw or other piece of power equipment should be brought indoors and given at least two hours to warm up before being used after being maintained in a chilly environment. Lubricants work better when warmed to room temperature. Even if you intend to use the tools outdoors, bring them inside to warm up before taking them outside to perform any drilling or cutting.

It’s crucial to take note of the recommended lubricants for outdoor use when buying pneumatic tools.

Storage for cordless power tools

It’s recommended to bring cordless power tools and their chargers indoors during the winter. In colder climates, batteries seem to discharge more quickly, and many cordless equipment come with a warning that the charger won’t work in a freezer.

Tools Powered by Gas

Gas-powered appliances like lawnmowers, chainsaws, and generators require particular care when storing during the winter. Lack of oil can cause corrosion, lack of gas can clog the carburettor and other parts, and moisture can interfere with ignition if an engine isn’t properly winterized. Typical actions throughout the winterization process include:

- Vanish the gas (or add a gasoline stabilizer). Emptying the gas from the tank solves the problem of varnishing fuel components caused by gas that has been sitting in the tank for more than a month. As an alternative, you might add fuel stabiliser to the tank.

- On 4-stroke motors, the oil needs to be replaced. This will stop the moving parts of the engine from adhering to the dirt and debris in the oil.

- Close the gas cap all the way. Engines emit emissions even when they are turned off in a very small amount. Wrap aluminium foil around the cap of a fuel tank with vents to prevent fuel from evaporating.

- Pull remove the spark plugs after turning off the battery. If the batteries are removable, they should be taken out of the mower and stored indoors for the winter.

Heat Generation in the Workshop

If you operate frequently in your garage or outdoor workshop during the cooler months, installing a heater is a wise choice. To get the room to a suitable temperature before work starts, you can either turn on the heaters just before you start working, or you can keep them on low all winter to keep the room above freezing. Even when kept at temperatures only slightly above freezing, tools can still be useful.

What to do if you already have rust

Seeing rust is not necessarily cause to completely demolish your shed. But there are measures you may do to try to get rid of the rust that’s already there and stop any more from forming.

- Rust can be removed with a steel brush and some white vinegar. Rust can be removed using vinegar and a scrubbing motion to loosen the rust from the surface. Depending on how bad the rust is, you may need to repeat this process multiple times.

- Even if the shed’s metal siding has holes, it can still be repaired. You can attempt a repair with epoxy repair putty designed for metal. Most of these items can be sanded down and painted over, making them ideal for repairing minor damage. Please read the product’s manual before using it.

- After determining that the surface needs to be removed, you can do it with a pressure cleaner. Make sure there is no dust, grease, grime, or mildew in the area and clean it well.

- Once the area you wish to safeguard is dry, wipe it down with a tack cloth. In the event that any chalk is transferred to the fabric, a steel brush should be used to remove the residue. When you’re through, give the area another pressure cleaning.

- After the structure has dried, a primer or finish can be applied. Paint the shed using a primer if you plan on changing the colour. Put on an acrylic coating designed for metal buildings if rust prevention is your only concern.

- To get the best results, give this coat at least two hours to dry, or as long as the manufacturer recommends. You are now in a good position to give the shed a second coat of paint.

To be absolutely confident that no additional parts of the shed have rusted or corroded, it is best to treat the entire structure.

How to remove rust?

A wire brush, steel wool, or a scouring pad can be used to remove stubborn rust. The rust can also be chemically removed off tools with the help of a number of commercially available treatments, most of which contain an acid that dissolves the rust. A good cleaning with a paste made of lime juice and salt will do the trick, according to grandma. The tools may also benefit from soaking in ordinary Coca-Cola for a few hours. The rust will have eaten away at the iron’s surface, leaving it scarred and pitted after cleaning. While polishing can restore the tool’s appearance, it cannot restore the metal’s structural integrity.

Avoid items that encourage dampness

There are a few things you can take to prevent moisture from getting into your shed and shortening its lifespan.

If your shed is equipped with gutters, keep them clean so that rainfall may freely drain. Mold and mildew can form if you let leaves and branches collect in your gutters, where they will absorb water and sit. It’s crucial to keep your gutters in good condition because this development won’t stop at the edges.

Avoid having soil and fancy gardens near the shed. While it may be tempting to create a beautiful garden bed around the outside of your new shed, doing so is actually detrimental to the shed’s lifetime. Since soils and plants can hold water, there will be a pool of moisture right next to your shed if you don’t maintain the space surrounding it free. When you go to water your garden, keep this in mind. In other words, you’d be pouring water quite close to your shed, if not directly over its walls. Keep the area around your shed clean of debris, long grass, leaves, and branches as much as possible to prevent excess moisture from accumulating there. Keeping the lawn maintained and the grounds clean is a must.

Keeping your garden shed or garage dry and mold-free over the winter and all year round may seem like an impossible effort, but with a few basic checks and sometimes the help of some extra equipment, it is entirely possible. Even while some parts of the backyard shed are more prone to water damage than others, it can all be avoided with a solid base.

A lot of the extra effort is unnecessary if the building process is followed properly, the right materials are used, and a strong base is laid. Keep in mind that the addition of windows to your garden shed is not just for aesthetics; they also serve as an extra layer of protection against the elements. In addition, you may need to spend a little extra on electrical fans or dehumidifiers to provide the proper storage environment for your items. If you want to keep the humidity in your shed low, it’s important to make sure the area around it doesn’t collect any moisture, and a bag of cat litter is an easy and inexpensive way to do just that. By remembering these guidelines, you can ensure that your shed will remain rust and corrosion free for many years.

Conclusion

Rust and corrosion can cause significant damage to your storage shed. There are a few things you can do to prevent rust and corrosion in your shed. This applies regardless of whether you live near saltwater or in a hot, humid climate. Even in a garage, your metal tools can rust. Any tool made, at least in part, of iron will rust within 3 to 5 days.

Stainless steel tools have been coated to resist rust. Copper isn’t as strong as steel, thus it’s unlikely that your hand tools are constructed of copper. Aluminium can form an oxidised corrosive layer even if it won’t rust. If some of your garage tools are beginning to rust, the best course of action is to remove it as soon as possible. Rust prevention can be achieved by dehumidifying your garage or using an anti-corrosive spray cleaner.

You can stop moisture from building up on your equipment if you instal a few fans around the area. The majority of hand tools can last for extended periods of time in the freezing conditions of a garage or storage shed without experiencing damage. If even a small amount of moisture is left on the tools, rust may reappear. Rust might become an issue if you bring them inside the house, particularly if you intend to store them in the basement. Power tools should be stored indoors if they are to be used all winter.

Lubricants work better when warmed to room temperature. Lack of oil can cause corrosion and lack of gas can clog the carburettor. moisture can interfere with ignition if an engine isn’t properly winterized. What to do if you already have rust in your shed or workshop. There are measures you may do to try to get rid of the rust.

Also consider using heaters to generate heat for working in the cold winter months, or turn off the spark plugs after turning off the battery. Rust can be removed with a steel brush and some white vinegar. Even if the shed’s metal siding has holes, it can still be repaired. To be absolutely confident that no additional parts of the shed have rusted or corroded, it is best to treat the entire structure. If your shed is equipped with gutters, keep them clean so that rainfall may freely drain.

Mold and mildew can form if leaves and branches collect in your gutters. Keep the area around your shed clean of debris, long grass, leaves, and branches as much as possible. Some parts of the backyard shed are more prone to water damage than others. A lot of the extra effort is unnecessary if the right materials are used. If you want to keep the humidity in your shed low, it’s important to make sure the area around it doesn’t collect any moisture.

Content Summary

- Rust and corrosion are only two of the maintenance concerns you’ll have to keep in mind for any size shed.

- There are a few things you can do to prevent rust and corrosion in your shed over the winter, regardless of whether you live near saltwater or in a hot, humid climate.

- However, even if you store them in a garage, they may still rust.

- Most importantly, keep in mind that rust may be avoided with the right equipment, storage solutions, and maintenance practises.

- Even in a garage, your metal tools can rust.

- Thankfully, the majority of stainless steel tools have been coated to resist rust.

- Metals like copper don’t rust.

- Although only iron and steel tools are known to rust when exposed to dampness, all tools will eventually undergo corrosion.

- You still need to take care of your tools so they don’t rust, even if you store them in a garage.

- How to Prevent Rusting in Your ToolsThe best way to get rid of rust is to prevent it in the first place.

- It doesn’t matter whether you keep your tools in the garage or the closet to prevent rusting.

- Using them ought to increase the longevity of your tools.

- Use an anticorrosive spray cleaner, such as the common WD-40, to remove rust.

- By keeping your toolbox organised, you can avoid a lot of accidents.

- Dehumidification of a garage Rust prevention for your tools can be achieved by dehumidifying your garage.

- Ventilate your garage with fresh air.

- With the aid of a dehumidifier and a garage fan, rust can be delayed for a long time.

- Put your toolkit in a safe place.

- If you neglect your garage tools, disaster is just a matter of time.

- How to Remove Rust from ToolsIf you see that some of your garage tools are beginning to rust, the best course of action is to detect it as soon as possible.

- Here is a quick and easy 4-step method to restore your garage tools if they have corroded over time:

- Make a tight ball out of some aluminium foil.

- To clean the dishes, fill a bowl with warm water and a few drops of dish soap.

- Repeat step three as necessary to achieve the desired results before drying your instruments and storing them in the garage.

- You can soak your tools and let the solution handle the difficult task of rust removal.

- Here are some tips for storing tools safely in the wintertime Hand Tool CabinetThe majority of hand tools can last for extended periods of time in the freezing conditions of a garage or storage shed without experiencing damage.

- To prevent this from happening, make it a routine to bring your hand tools inside from the garage or shed at least an hour before you want to use them.

- Additionally, remember that metal tools corrode with time.

- Try to find a safe location inside the house to store your tools if you are concerned about rust.

- In extremely cold climates where the air is regularly dry, tools are less likely to rust throughout the winter.

- Clean the underside of your lawnmower deck to get rid of any stray grass clippings, and scrub the power tiller blades well to get rid of any corrosion or rust.

- Power Tool CabinetIf used in extremely cold temperatures, your power tools, like any powered instrument, may encounter considerable strain.

- Power tools should be stored indoors if they are to be used all winter due to the cold.

- Storage for cordless power toolsIt’s recommended to bring cordless power tools and their chargers indoors during the winter.

- Vanish the gas (or add a gasoline stabilizer).

- Emptying the gas from the tank solves the problem of varnishing fuel components caused by gas that has been sitting in the tank for more than a month.

- As an alternative, you might add fuel stabiliser to the tank.

- This will stop the moving parts of the engine from adhering to the dirt and debris in the oil.

- Close the gas cap all the way.

- Wrap aluminium foil around the cap of a fuel tank with vents to prevent fuel from evaporating.

- Pull remove the spark plugs after turning off the battery.

- If the batteries are removable, they should be taken out of the mower and stored indoors for the winter.

- Heat Generation in the WorkshopIf you operate frequently in your garage or outdoor workshop during the cooler months, installing a heater is a wise choice.

- To get the room to a suitable temperature before work starts, you can either turn on the heaters just before you start working, or you can keep them on low all winter to keep the room above freezing.

- What to do if you already have rustSeeing rust is not necessarily cause to completely demolish your shed.

- Rust can be removed with a steel brush and some white vinegar.

- Rust can be removed using vinegar and a scrubbing motion to loosen the rust from the surface.

- Even if the shed’s metal siding has holes, it can still be repaired.

- After determining that the surface needs to be removed, you can do it with a pressure cleaner.

- Make sure there is no dust, grease, grime, or mildew in the area and clean it well.

- When you’re through, give the area another pressure cleaning.

- Paint the shed using a primer if you plan on changing the colour.

- You are now in a good position to give the shed a second coat of paint.

- The rust will have eaten away at the iron’s surface, leaving it scarred and pitted after cleaning.

- There are a few things you can take to prevent moisture from getting into your shed and shortening its lifespan.

- If your shed is equipped with gutters, keep them clean so that rainfall may freely drain.

- It’s crucial to keep your gutters in good condition because this development won’t stop at the edges.

- Avoid having soil and fancy gardens near the shed.

- When you go to water your garden, keep this in mind.

- Keep the area around your shed clean of debris, long grass, leaves, and branches as much as possible to prevent excess moisture from accumulating there.

- Keeping the lawn maintained and the grounds clean is a must.

- Even while some parts of the backyard shed are more prone to water damage than others, it can all be avoided with a solid base.

- A lot of the extra effort is unnecessary if the building process is followed properly, the right materials are used, and a strong base is laid.

- Keep in mind that the addition of windows to your garden shed is not just for aesthetics; they also serve as an extra layer of protection against the elements.

- In addition, you may need to spend a little extra on electrical fans or dehumidifiers to provide the proper storage environment for your items.

- If you want to keep the humidity in your shed low, it’s important to make sure the area around it doesn’t collect any moisture, and a bag of cat litter is an easy and inexpensive way to do just that.

FAQs About Garage Rust

Why does my garage door keep rusting?

The bottom of the door is particularly vulnerable to rust because that’s where water and other corrosive elements like road salt and sand tend to pool. And if you happen to be a resident of a coastal area, you can add the corrosive effects of salty, humid air to the list of problems you’ll have with rust.

What fixes rust on a garage door?

Bondo, sold at auto supply stores, can be used to patch the damage. You can use a putty knife to apply the Bondo, and then sand down any rough spots with some sandpaper. If more Bondo is required to get it to a uniform colour with the garage door, apply it.

How can I prevent the rusting of my garage door?

Use wax. Wax not only acts as a lubricant but also as a protective layer to keep the garage door’s finish free of rust. Waxing the garage door helps keep salt from sticking to the moving parts and keep buildup of dirt and grime to a minimum.

Garage door rust: can it be painted over?

Ineffective because paint will not stick to rusty metal. The door must be stripped of rust, cleaned, and primed to prevent further rusting. The success of the paint job depends on using a high-quality rust-inhibiting paint thereafter.

How about the garage door?

Many different materials, including steel, wood, fibreglass, and aluminium, are used to make garage doors. Besides their outwardly visible differences in appearance, garage door materials can also vary by price, climatic resistance, and design preferences.